-40%

NuVinci N171B IGH / CVT Hub - Manual Shifting Version

$ 79.2

- Description

- Size Guide

Description

The Legendary NuVinci N171 Continuously Variable Transmission HubStrongest CVT (like IGH but continuously variable shift ratio) available, compatible with BBSHD and comparably powered mid drives

Rare and Sought After, Long Discontinued

Very Reliable and we have stock of Supplies and Rebuild Kits

Available in Black 32H, or Silver 36H

Everything but cable housing included (need 2x cable housing as there are dual upshift and downshift lines)

Gear Sensor Highly Recommended (will not shift under load)

Can shift around 40% at standstill

Ultimate Hub for pairing with E-bike Mid Drive Motor Kits

Brake Options: Rim, Disc, or Roller Brake

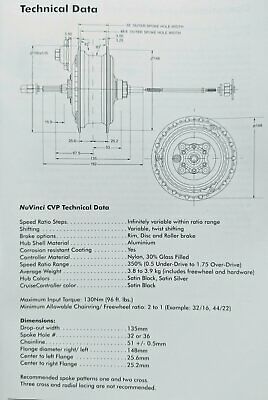

Speed / Ratio Range: 350% (0.5 Under-Drive and 1.75 Over-Drive)

Speed / Ratio Steps: Infinite Variable within Ratio Range

Hub Shell Material : Aluminum w/ Corrosion Resistant Coating

Weight: <8.75lb>

Includes:

- NuVinci N171 Hub (Black 32H or Silver 36H)

- NuVinci hub axle parts and shift box

- NuVinci grip shifter with dual cables

Note: the disc brake adapter (pictured with kit for reference) is NOT included. The disc brake adapters have limited availability but can be purchased separately

Description:

The NuVinci N171 is the best type of internally geared hub to use with mid drive ebike units like the Bafang BBSHD Mid Drive Kit - utilizing NuVinci CVT Technology, the N171 doesn't use gears - just butter smooth shifting to the perfect ratio desired. CVT stands for Continuously Variable Transmission. The N171 uses conical drives with steel balls in a special non-newtonian oil to transfer power. This early version was overbuilt and a bit too heavy for a regular bicycle – but perfect for an ebike where weight is less of a concern.

It is recommended to run a gear sensor on one of the cables when trying to shift under load. Also, you can run full length housing as there’s no indexing. This makes it a truly maintenance free solution as the cables are well protected. In addition we have stock of spare parts, special oil and shifters ~ should you need any servicing later on.

Tips for setting up the shifter:

1. When operating the hub with electric assist, put a gear sensor in line with the shift cables so the motor stops powering when attempting to operate the shifter. The N171 does not shift under load.

2. Run full housing. It protects the cables and there’s no advantage to not having full coverage.

3. For easier installation, install an extra cable housing adjuster barrel in one of the cables. It allows for less precision when establishing cable length on the initial setup.

Known issues that can develop over the years:

1. Heat.

In hot climates and under hard use, some hubs will leak oil. It appears to be caused by the large hub shell expanding slightly and allowing the black threaded plate to lose it’s seal. We’ve opened them up and wrapped the threads with teflon tape. Warming up the hub shell (expanding it) before closing it back up again will further help seal it. Note that it’s difficult to break the seal on a new hub if you have the thought to do this job preemptively. It’s recommended to not try this as most hubs don’t leak.

2. Hub mounted brakes.

Powerful hub mounted brakes can slowly work the black threaded plate loose. If the three locking teeth come loose at all, the seal can be broken. Excessive braking under heavy load can also heat the hub up (see #1 above). The three locking teeth are held on with three button head cap screws. It is recommended to replace those screws with a torx head screw. These should be reinstalled with permanent thread locking compound (red LocTite) and checked periodically.

3. Shifter wear

: The handlebar mounted shifter mechanism can wear out. It’s difficult to fix. Often just the cable is damaged and continued use with a damaged cable will hasten the demise of the shifter. Best to replace the shifter.

4. Shift box vulnerability

. The shift box hangs off the end of the hub and can get damaged. If a guard can be made to protect the shift box, it will last a lot longer. The shift rod that inserts into the hub can also get bent but they can be bent back straight with some effort.

5. Freewheel removal.

The NuVinci N171 is threaded for a freewheel but the system already is able to run backwards, like a freewheel but with some resistance. And most mid drive electric assist units (like the Bafang HD series) have freewheeling in the crankset. So we usually just install a track cog on the threaded portion and it’s more easily removed. Fallbrook sold a removal tool but they are no longer available. With the track cog, you just remove a snap ring and the freewheel body can come off, allowing access to the back side for fixing with various methods (including using a tool we have available) as you then use a chain whip to unscrew the track cog. If there’s a regular freewheel on it, you have to pry it off, overpowering the snap ring. This is surprisingly easy to do with a big screwdriver but you run the risk of damaging the snap ring. Then use the 'freewheel carrier holder' tool to hold it in a vise, and use the chain whip to remove the freewheel. We have spare snap rings but they are expensive because we harvest them from other hubs, along with fluid and other parts.

Documentation:

Additional Search Tags: NuVinci Fallbrook N171B N 171 N-171 C.V.T. Continuously IGH I.G.H Internal Internally Gear Geared Hub